Today’s semiconductor ecosystem is facing significant inventory shortages, resulting in extended lead times and increased demand. Engineering teams are rapidly adapting to this new ecosystem by iterating on project requirements, making it even more challenging to plan, scope and vet potential supplier partners. As a result, it’s more important now than ever to receive accurate lead times and fast quote responses so that you can effectively forecast your projects and plan your budgets.

Today’s semiconductor ecosystem is facing significant inventory shortages, resulting in extended lead times and increased demand. Engineering teams are rapidly adapting to this new ecosystem by iterating on project requirements, making it even more challenging to plan, scope and vet potential supplier partners. As a result, it’s more important now than ever to receive accurate lead times and fast quote responses so that you can effectively forecast your projects and plan your budgets.

To alleviate some of the issues brought about by these unique market conditions, we’ve developed this blog to help you receive the quote information you need from Criteria Labs quickly and with as little back and forth as possible.

Before jumping into each of our service areas we’d like to mention that the below four project details are applicable to each category of Criteria Labs services.

- Whether your project is in support of a space, defense or military application.

- A detailed Project Scope and/or Statement of Work.

- If available, a budget range or specific cost requirement.

- Your desired project lead time(s).

RF Design:

You have unique engineering design needs, we have the in-house capabilities to complement your internal teams and help you meet your stringent project requirements. Whether you are designing your next RF hybrid Multi-chip Module (MCM), Integrated Microwave Assembly (IMA), System in Package (SIP), test board or stress card, our in-house Design Engineers can complement your internal teams and help you achieve project success.

You have unique engineering design needs, we have the in-house capabilities to complement your internal teams and help you meet your stringent project requirements. Whether you are designing your next RF hybrid Multi-chip Module (MCM), Integrated Microwave Assembly (IMA), System in Package (SIP), test board or stress card, our in-house Design Engineers can complement your internal teams and help you achieve project success.

Quote Criteria Considerations:

- Is your project a new design, design to specification or build to print?

- For build to print we require the device drawings. Also, if the materials will be provided or turn-key supply chain. Criteria Labs has the capability to procure materials if required.

- If design to specification please let us know if you’ve attempted the design before. If there are any risks our Design Engineers should take into consideration.

- We’ll need to know the component type, if it is an RF component we’ll need to know the frequency range.

- Do you require firm fixed pricing or Rough Order of Magnitude (ROM) pricing?

- The required packaging type (Ex: hermetic, leadless, leaded).

RF Package Assembly:

Criteria Labs has extensive build to print capabilities to manufacture complex products ranging from ceramic LTCC and HTCC hermetic assemblies, to high reliability printed circuit boards, single chip and Multi-chip hybrid modules for high frequency RF applications. Our class 100 packaging facility and clean room is ISO 9001:2015 and 17025:2017 certified.

Criteria Labs has extensive build to print capabilities to manufacture complex products ranging from ceramic LTCC and HTCC hermetic assemblies, to high reliability printed circuit boards, single chip and Multi-chip hybrid modules for high frequency RF applications. Our class 100 packaging facility and clean room is ISO 9001:2015 and 17025:2017 certified.

Quote Criteria Considerations:

- If an RF application, the desired frequency range.

- The packaging material requirements (Ex: organic, plastic or ceramic).

- Will the power dissipation require sauder or thermal epoxy?

- Will a heat spreader be required?

- The printed circuit board material that the device/component will mate to.

- The required packaging type (Ex: space qualified hermetic).

- Will the packaged part require qualification?

RF Qualification, Test and Screening:

Criteria Labs has the capability to perform qualification, testing and screening on a broad range of RF products including; Microcircuits, Semiconductors, Passives, Connectors and Filters. Our experienced Reliability Engineers can create qualification plans and perform testing to meet your requirements with strict adherence to applicable MIL-STD-883, MIL-STD-750, MIL-STD-202, JEDEC, AEC-Q100/Q200 and TELCORDIA specifications.

Criteria Labs has the capability to perform qualification, testing and screening on a broad range of RF products including; Microcircuits, Semiconductors, Passives, Connectors and Filters. Our experienced Reliability Engineers can create qualification plans and perform testing to meet your requirements with strict adherence to applicable MIL-STD-883, MIL-STD-750, MIL-STD-202, JEDEC, AEC-Q100/Q200 and TELCORDIA specifications.

Quote Criteria Considerations:

- We’ll need to know whether or not you have defined qualification, test or screening procedures in place. If not, we can assist in developing the procedures.

- A detailed itemization of the qualification, test and screening requirements. To include detailed methodologies if required and/or available. (Ex: wafer probing, RF testing of packaged devices, direct current, parametric, photonics, etc.).

- Any specific technology capabilities that is required (Ex: CMOS, GaN, etc.).

- When it comes to qualification, test and screening Criteria Labs utilizes both manual and automated equipment. Our on-site equipment includes; HAST, THB, Pre-conditioning, Leak Testing, Thermal Shock, MSL Sensitivity, Vibration, Burn-in and life test ovens.

- If your qualification, test or screening project requires specific equipment that we do not have on site will you provide it for us? We can work with your team to buy, lease, or rent required equipment if necessary.

- Will your project need to meet any specific certification levels? Our experienced Reliability and Test Engineers can create qualification, test and screening plans to meet your project requirements with strict adherence to applicable specifications.

- Is your project for a space application? Space level certifications can vary greatly depending on the project requirements, you may want to check-out our Managing Space Grade RF Device Qualifications to help you plan accordingly.

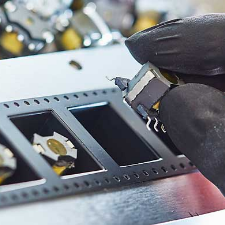

Tape and Reel Packaging:

Criteria Labs is the largest domestic tape and reel provider in the United States with the extensive capabilities to address all of your tape and reel packaging needs. We can process the smallest of orders to the largest, to infrequent orders and daily deliveries. We conduct all of our tape and reel packaging operations at our Penrose, Colorado facility. Our tape and reel packaging operations facility has the capacity to process millions of parts each month.

Criteria Labs is the largest domestic tape and reel provider in the United States with the extensive capabilities to address all of your tape and reel packaging needs. We can process the smallest of orders to the largest, to infrequent orders and daily deliveries. We conduct all of our tape and reel packaging operations at our Penrose, Colorado facility. Our tape and reel packaging operations facility has the capacity to process millions of parts each month.

Quote Criteria Considerations:

- The quantity of parts that need to be handled.

- Your requested lead time(s). Our lead times are generally 3-4 days. We also offer expedited same-day and next-day options.

- The manufacturer’s part number.

- Any specific certification standards that must be met. Criteria Labs Tape and Reel Service is ISO 9001 certified for quality service.

- Custom bar coding and labeling information if required.

- Will custom designed carrier tape be required? Criteria Labs possesses a large inventory of carrier tape for purchase, including custom solutions.

- Do you have a specific tape and reel packaging capabilities requirement? Click here to view an itemization of our capabilities as well as the specific devices that we can process.

- Do you know what to look for when vetting potential Tape and Reel packaging partners? If not, you may want to check-out our blog, “Our Best Tips for Selecting a Tape and Reel Packaging Vendor.”

Want to stay up-to-date on the latest content and news from Criteria Labs?