Viable, cost-effective, and sustainable upscreening solutions

As encapsulated microcircuits and other devices continue to play a growing role in Defense and Space applications, designers are forced to increase their requirements beyond OEM specifications. This increase in performance requirements ensures that devices can be used in non-commercial applications with confidence. Specifically, that the device can operate outside of the commercial temperature range, meet tighter electrical tolerances, and mitigate infant mortality device failure risk.

As encapsulated microcircuits and other devices continue to play a growing role in Defense and Space applications, designers are forced to increase their requirements beyond OEM specifications. This increase in performance requirements ensures that devices can be used in non-commercial applications with confidence. Specifically, that the device can operate outside of the commercial temperature range, meet tighter electrical tolerances, and mitigate infant mortality device failure risk.

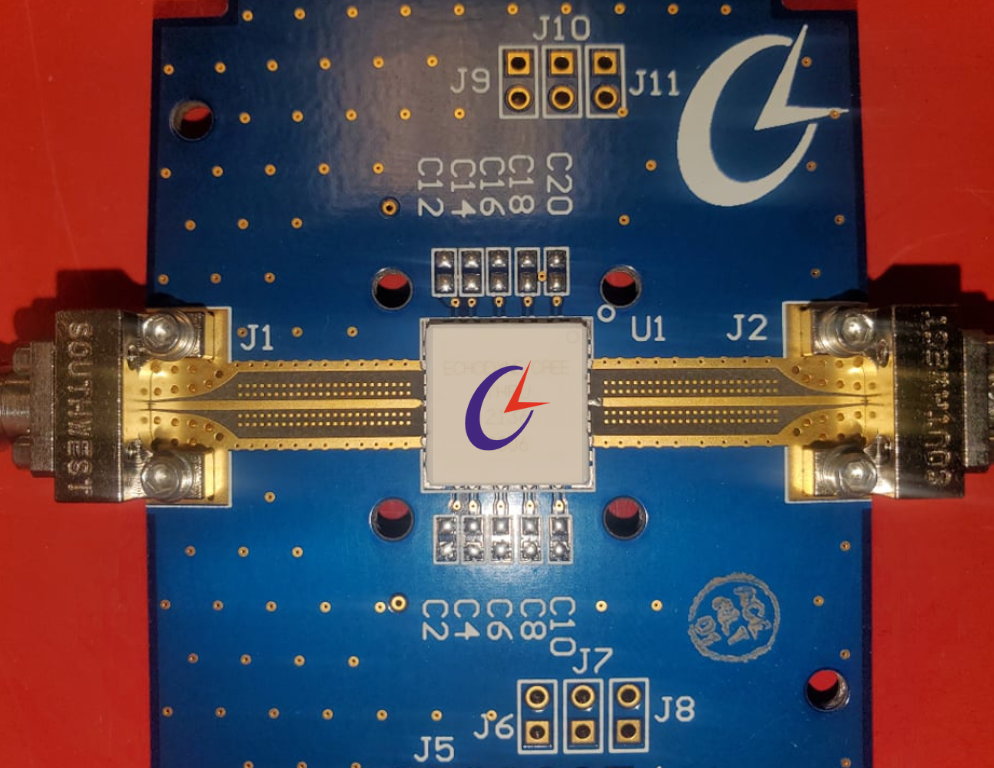

Our purpose-built facility located in Austin, Texas uses in-house resources to provide a complete solution for defense and space-certified semiconductors. Upscreening solutions from Criteria Labs guarantees the availability of semiconductor components that may no longer be available.